Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

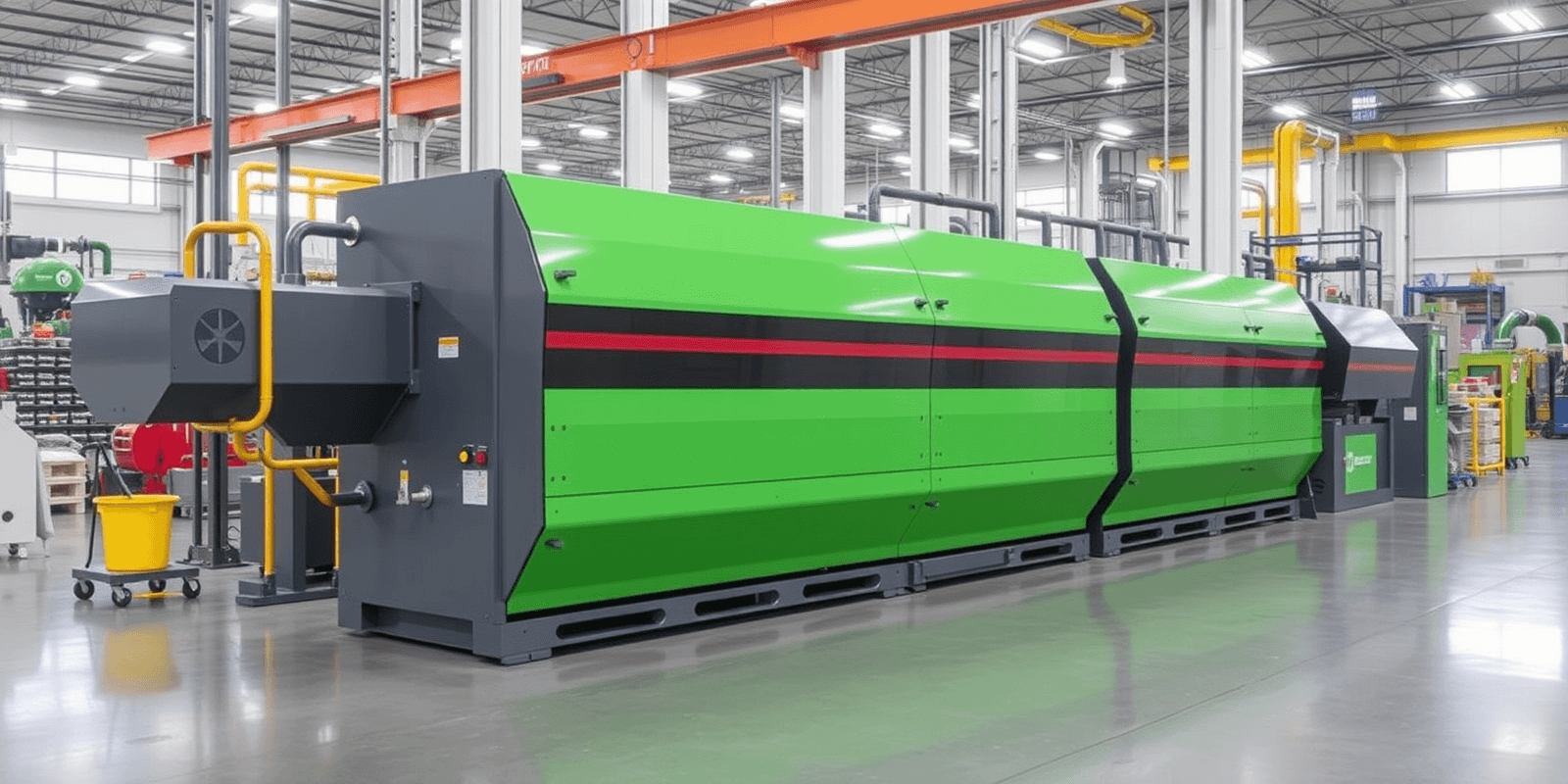

In today’s world, the importance of sustainability and environmental responsibility cannot be overstated. As industries strive to reduce their ecological footprint, plastic reprocessing machines for manufacturing have emerged as a pivotal tool in creating a circular economy. These innovative machines play a crucial role in waste reduction, resource efficiency, and promoting sustainability in manufacturing. This article will explore how plastic reprocessing machines are transforming the manufacturing landscape and contributing to a more sustainable future.

One of the most significant challenges facing modern manufacturing is the management of plastic waste. According to a report by the United Nations Environment Programme (UNEP), the global production of plastics has increased exponentially over the past few decades, leading to a surge in plastic waste. This waste not only pollutes our environment but also poses a threat to wildlife and human health.

Plastic reprocessing machines for manufacturing offer a solution to this problem by converting post-consumer and industrial plastic waste into reusable materials. These machines use advanced technologies such as shredding, washing, and extrusion to break down and purify plastic waste, making it suitable for reuse in new products. By doing so, they significantly reduce the amount of plastic waste that ends up in landfills and oceans, thereby mitigating the environmental impact of plastic pollution.

Resource efficiency is another key aspect of sustainable manufacturing. Traditional manufacturing processes often rely on virgin materials, which are extracted and processed at a high environmental cost. In contrast, plastic reprocessing machines for manufacturing enable the use of recycled materials, reducing the need for new raw materials and conserving natural resources.

These machines not only help in recycling plastic waste but also improve the overall efficiency of the manufacturing process. For instance, they can handle a wide range of plastic types, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), making them versatile and adaptable to different manufacturing needs. Additionally, the use of recycled plastic can lead to cost savings for manufacturers, as recycled materials are often less expensive than virgin materials.

The field of plastic reprocessing is constantly evolving, with new innovations emerging to enhance the efficiency and effectiveness of these machines. One such innovation is the development of advanced sorting technologies, which use sensors and artificial intelligence to accurately identify and separate different types of plastics. This ensures that the recycled material is of high quality and suitable for various applications.

Another notable advancement is the integration of energy-efficient systems in plastic reprocessing machines. These systems minimize energy consumption during the reprocessing process, further reducing the environmental impact. For example, some machines use heat recovery systems to capture and reuse the heat generated during the melting and extrusion processes, leading to significant energy savings.

Moreover, the use of biodegradable and bio-based plastics in conjunction with plastic reprocessing machines is gaining traction. These materials, derived from renewable sources, can be processed using the same reprocessing technologies, offering a more sustainable alternative to conventional plastics. This approach not only reduces the reliance on fossil fuels but also promotes the use of eco-friendly materials in manufacturing.

The adoption of plastic reprocessing machines for manufacturing is a critical step towards achieving a more sustainable and circular economy. By reducing waste, enhancing resource efficiency, and embracing innovative technologies, these machines contribute to a more environmentally friendly manufacturing process. However, the success of this transition depends on the collaboration between manufacturers, policymakers, and consumers.

Manufacturers must invest in these technologies and integrate them into their production processes. Policymakers can support this transition by implementing regulations and incentives that encourage the use of recycled materials and sustainable practices. Consumers, too, play a vital role by choosing products made from recycled materials and supporting companies that prioritize sustainability.

Plastic reprocessing machines for manufacturing are a game-changer in the quest for a more sustainable and circular economy. They offer a practical and effective solution to the growing problem of plastic waste, while also enhancing resource efficiency and promoting innovation in the manufacturing sector. As we continue to face the challenges of environmental degradation and resource depletion, the adoption of these machines is essential for a greener and more sustainable future.

By working together, we can harness the power of plastic reprocessing technology to create a manufacturing industry that is both economically viable and environmentally responsible. The time to act is now, and the tools are at our disposal. Let us embrace this opportunity to build a better, more sustainable world.