Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Plastic waste is one of the most pressing environmental challenges of our time. As we generate more plastic waste than ever before, it becomes increasingly important to find effective solutions for managing and reducing this waste. One such solution is the use of plastic shredder machines for recycling. These machines play a crucial role in converting plastic waste into valuable recyclable material. In this article, we will explore the process of using plastic shredder machines for waste reduction, from collecting plastic waste to turning it into usable materials.

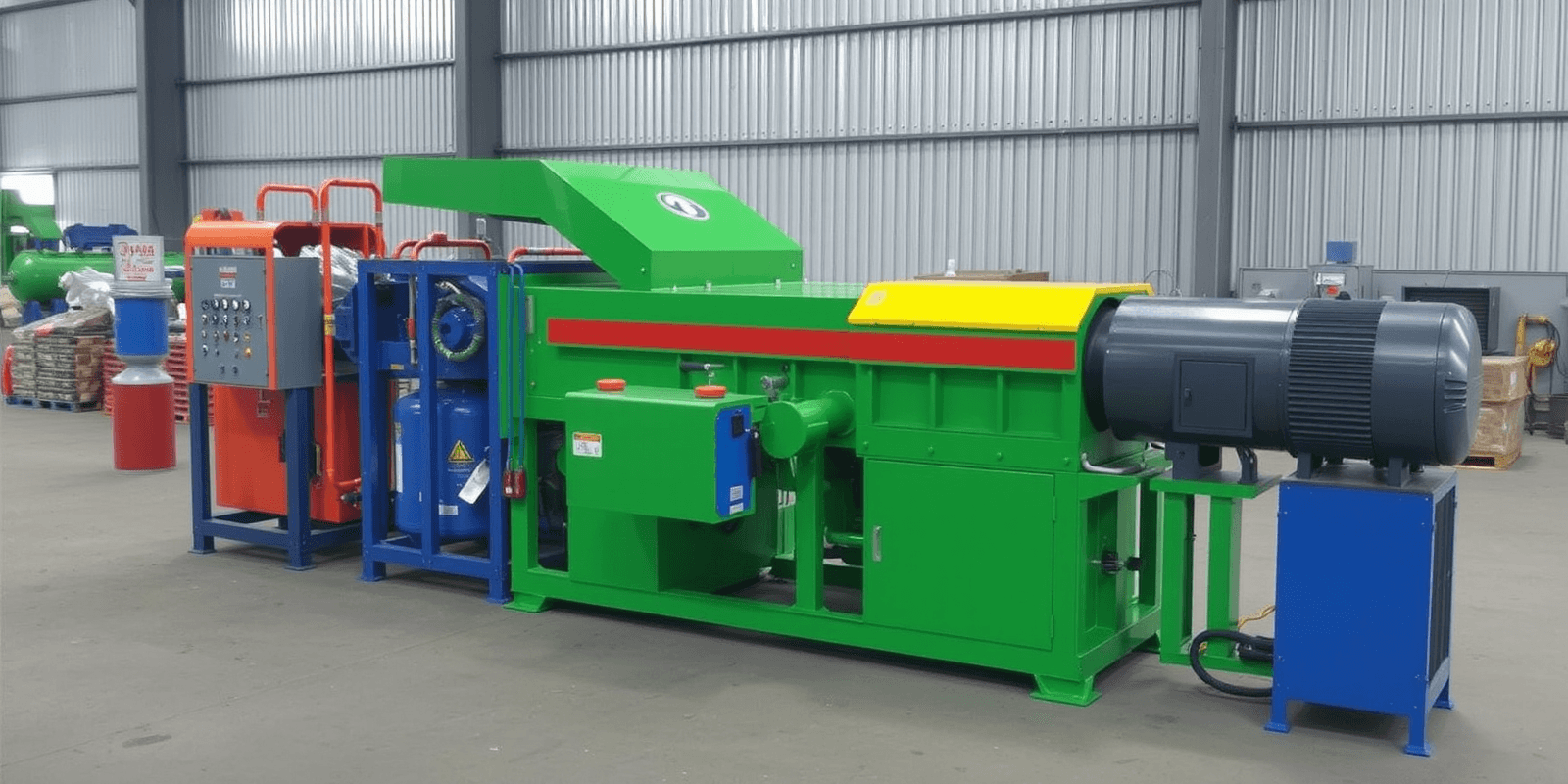

Plastic shredder machines are essential tools in the fight against plastic pollution. They break down large pieces of plastic waste into smaller, manageable pieces that can be processed more efficiently. By reducing the size of plastic waste, these machines make it easier to transport, store, and recycle the material. Additionally, shredding plastic waste increases its surface area, making it more accessible for chemical treatments and mechanical processes involved in recycling.

The journey of plastic waste begins with collection. This process involves gathering plastic waste from various sources such as households, businesses, and public spaces. Effective collection systems are critical for ensuring a steady supply of plastic waste for recycling facilities. Local governments, waste management companies, and community organizations often collaborate to implement efficient collection programs. These efforts help prevent plastic waste from ending up in landfills or oceans, where it can cause significant environmental harm.

Once collected, plastic waste must be sorted and prepared for processing by plastic shredder machines. Sorting involves separating different types of plastics based on their resin identification codes (RICs) or other distinguishing characteristics. This step is crucial because not all plastics can be recycled together due to differences in melting points and chemical compositions. After sorting, the plastic waste is cleaned to remove contaminants like dirt, food residue, and labels. Proper cleaning ensures that the shredded plastic is of high quality and suitable for recycling.

The core function of plastic shredder machines is to break down plastic waste into smaller pieces. These machines use sharp blades or rotating discs to cut through plastic items, reducing them to small chips or flakes. The size of the shredded pieces can vary depending on the specific requirements of downstream recycling processes. For instance, some recycling facilities may require very fine particles for certain applications, while others may prefer larger chunks for other purposes. The shredding process also helps to separate mixed plastics by density, making it easier to handle and process different types of plastic waste.

After shredding, the plastic waste undergoes further processing to prepare it for recycling. This may include washing to remove any remaining contaminants, drying to ensure the material is free of moisture, and sorting to remove any non-plastic components. Depending on the type of plastic and intended end-use, additional treatments such as decontamination or color sorting may be necessary. Once the shredded plastic is properly processed, it is ready for incorporation into new products or materials.

The final step in the process is recycling and reuse. The shredded plastic can be used to create a wide range of products, including new plastic containers, packaging materials, construction materials, and even clothing fibers. Recycling plastic not only reduces the amount of waste sent to landfills but also conserves resources and energy compared to producing virgin plastic. By reintroducing recycled plastic into the manufacturing cycle, we can significantly reduce our reliance on non-renewable resources and minimize environmental impact.

Plastic shredder machines are indispensable tools in the effort to reduce plastic waste and promote sustainable recycling practices. From collecting plastic waste to turning it into valuable recyclable material, these machines play a pivotal role in transforming discarded plastic into resources for new products. By implementing efficient collection systems, proper sorting and preparation techniques, and advanced shredding technologies, we can make significant strides in mitigating the environmental impact of plastic waste. It is crucial for individuals, communities, and industries to work together to support and invest in these recycling initiatives for a cleaner, more sustainable future.