Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

“`html

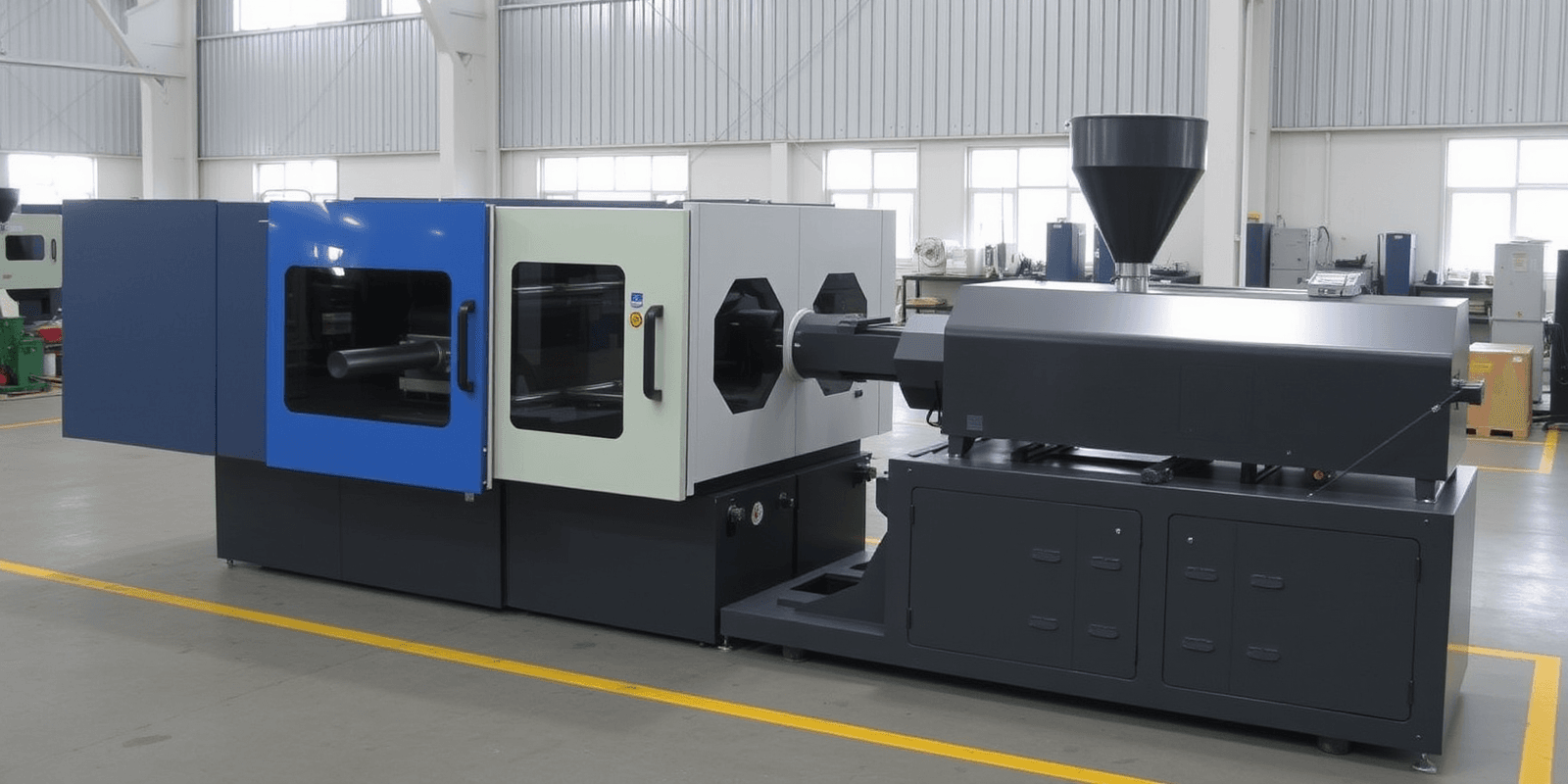

In the manufacturing industry, plastic molding machines are essential for producing a wide range of products. To ensure these machines operate at their peak efficiency, regular maintenance is crucial. This article will guide you through the step-by-step process of maintaining plastic molding machines, highlighting the importance of regular cleaning, lubrication, calibration checks, and preventive maintenance schedules. By following these guidelines, you can minimize downtime, reduce costs, and improve overall productivity.

Regular cleaning is a fundamental aspect of maintaining plastic molding machines. Dust, debris, and other contaminants can accumulate over time, affecting the machine’s performance and potentially causing damage. Here’s how to clean your plastic molding machine effectively:

Regular cleaning not only keeps the machine in good working condition but also extends its lifespan. For example, a study by the Society of Plastics Engineers (SPE) found that proper cleaning practices can extend the life of plastic molding machines by up to 30% (SPE, 2022).

Lubrication is another critical component of maintaining plastic molding machines. Proper lubrication ensures that moving parts operate smoothly, reducing wear and tear and preventing overheating. Here’s how to lubricate your machine:

A well-lubricated machine runs more efficiently and requires less energy, which can lead to significant cost savings. According to the American Society of Mechanical Engineers (ASME), properly lubricated machines can reduce energy consumption by up to 15% (ASME, 2021).

Calibration checks are vital to ensure that your plastic molding machine operates accurately and produces consistent results. Calibration involves verifying and adjusting the machine settings to ensure they meet specified standards. Here’s how to perform calibration checks:

Accurate calibration is crucial for maintaining product quality and consistency. The National Institute of Standards and Technology (NIST) emphasizes the importance of regular calibration checks to ensure accurate measurements and reliable results (NIST, 2023).

Implementing a preventive maintenance schedule is an effective way to anticipate and prevent potential issues before they become major problems. A preventive maintenance plan typically includes regular inspections, part replacements, and system upgrades. Here’s how to create a preventive maintenance schedule:

A proactive approach to maintenance can significantly reduce unexpected breakdowns and extend the machine’s lifespan. The International Society of Automation (ISA) recommends implementing preventive maintenance schedules to minimize unplanned downtime and optimize machine performance (ISA, 2022).

Despite regular maintenance, plastic molding machines may still encounter common issues that can affect their performance. Being able to identify and address these issues promptly is crucial for maintaining machine efficiency. Here are some common issues and how to handle them:

By addressing these common issues promptly, you can maintain the machine’s performance and avoid costly repairs. The Plastics Industry Association (PIA) provides comprehensive guides on troubleshooting common issues in plastic molding machines (PIA, 2023).

Maintaining plastic molding machines efficiently is essential for ensuring optimal performance and productivity. By following a structured maintenance plan that includes regular cleaning, lubrication, calibration checks, and preventive maintenance schedules, you can keep your machines running smoothly. Identifying and addressing common issues promptly is also key to minimizing downtime and extending the machine’s lifespan. Implementing these best practices will help you achieve higher efficiency, better product quality, and reduced operational costs.

SPE (2022): Society of Plastics Engineers. Retrieved from https://www.spe.org/

ASME (2021): American Society of Mechanical Engineers. Retrieved from https://www.asme.org/

NIST (2023): National Institute of Standards and Technology. Retrieved from https://www.nist.gov/

ISA (2022): International Society of Automation. Retrieved from https://www.isa.org/

PIA (2023): Plastics Industry Association. Retrieved from https://www.plasticsindustry.org/

“`